Mechanics rely on different types of tools to do repairs, check systems, or install parts correctly. These tools include hand tools, diagnostic devices, and power-driven machines. Every item plays a unique role in daily mechanical work, from loosening bolts to testing circuits. This blog post helps learn mechanic tools names in English with clear examples. It’s useful in garages, repair shops, or while training as a technician.

Table of Contents

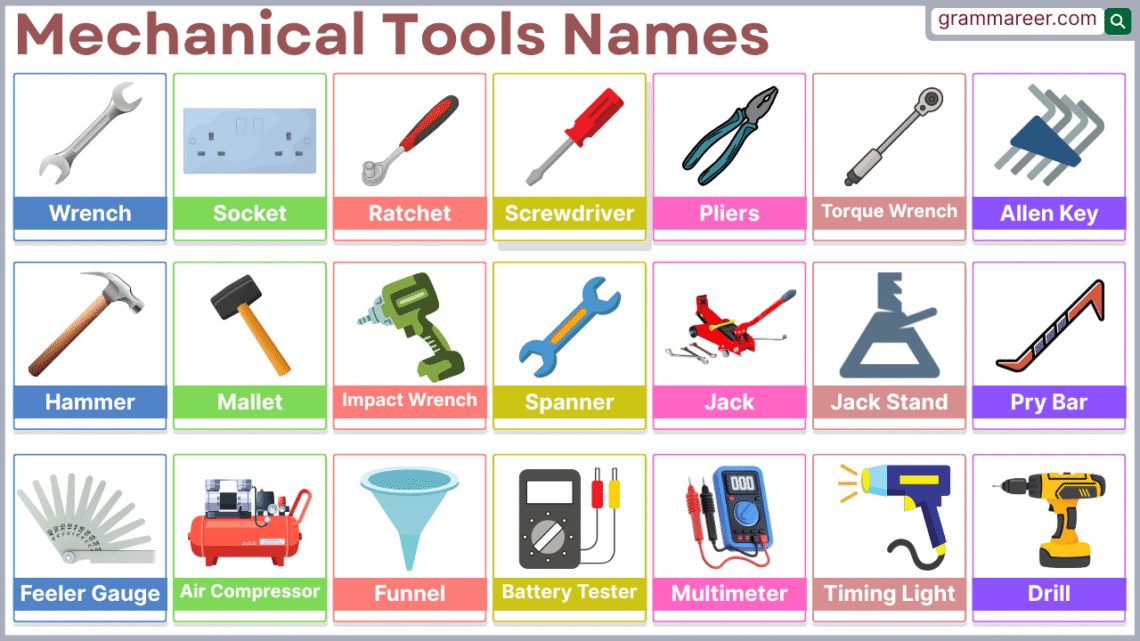

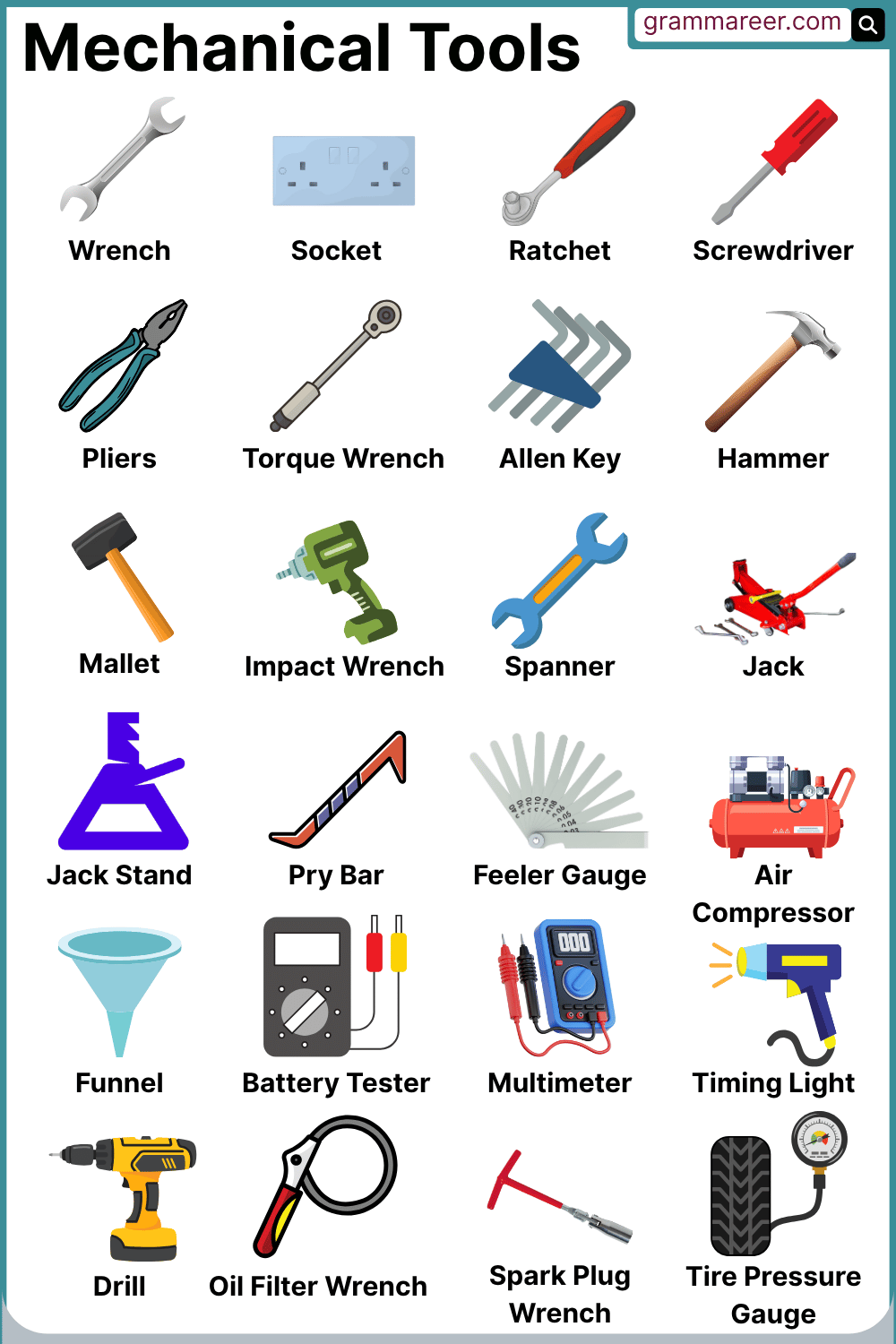

Common Mechanic Tools List with Pictures

Mechanic tools are essential for fixing, diagnosing, and maintaining all types of machines and vehicles. From basic hand tools to advanced diagnostic devices, mechanics use a wide range of equipment to complete daily repair tasks accurately. Here is a list of mechanic tools names.

- Wrenches

- Socket Set

- Ratchet Wrench

- Torque Wrench

- Screwdrivers

- Pliers

- Allen Wrenches

- Hammers

- Pry Bar

- Utility Knife

- Impact Wrench

- Drill

- Angle Grinder

- Electric Screwdriver

- Heat Gun

- Air Ratchet

- Multimeter

- Tire Pressure Gauge

- Micrometer

- Caliper

- Timing Light

- OBD2 Scanner

- Floor Jack

- Jack Stands

- Creeper

- Work Light

- Oil Drain Pan

- Funnel

- Tool Chest

Types of Hand Tools Every Mechanic Uses

Hand tools are the backbone of any mechanic’s kit. They’re used for gripping, turning, hitting, and assembling parts. Below are common types of hand tools mechanics use daily.

Different Wrenches Names

- Adjustable Wrench: Versatile tool used for turning nuts and bolts of different sizes.

- Box-End Wrench: Encloses the bolt or nut completely for better grip.

- Combination Wrench: Has one open end and one box-end for flexibility.

Screwdrivers

- Flathead Screwdriver: Used for screws with a straight, single slot.

- Phillips Screwdriver: Fits cross-shaped screw heads, common in car interiors.

- Torx Screwdriver: Star-shaped tip for specific automotive screws.

Hammers Names

- Ball Peen Hammer: Used in metalwork to shape or strike metal parts.

- Rubber Mallet: Delivers softer blows without damaging surfaces.

- Claw Hammer: Useful for light carpentry in garage setups.

Pliers list

- Needle Nose Pliers: Reaches tight spaces and grips small wires.

- Slip Joint Pliers: Adjustable jaws for general gripping.

- Locking Pliers (Vise-Grips): Locks onto bolts or components for a secure hold.

Power Tools Types Used in Mechanical Work

Power tools help save time and reduce manual effort. They run on electricity or batteries and are key to efficient repairs. Below are the most used power tools in mechanical jobs.

Drills Names

- Cordless Drill: Used for drilling holes or driving screws. Convenient and mobile.

- Hammer Drill: Adds a hammering motion, useful for hard surfaces.

Grinders

- Angle Grinder: Cuts, grinds, or polishes metal surfaces.

- Bench Grinder: Mounted for sharpening and shaping tools.

Impact Wrenches

- Cordless Impact Wrench: Delivers high torque, ideal for removing lug nuts or bolts.

- Pneumatic Impact Wrench: Air-powered for heavy-duty automotive use.

Cutting Tools

- Reciprocating Saw: Cuts through metal or exhaust pipes with a push-pull motion.

- Cut-Off Tool: Designed for precision cutting of metal rods or panels.

- Angle Grinder with Cutting Disc: A versatile option for slicing through metal sheets.

Diagnostic Tools Used by Mechanics

Diagnosing problems accurately saves time and prevents future breakdowns. These tools help read signals, test performance, and locate faults. Here’s a list of common mechanic diagnostic tools.

- Multimeters: Measures voltage, current, and resistance. Helps identify electrical issues in circuits or batteries.

- OBD Scanners: Connects to a vehicle’s computer to read error codes and sensor data. Essential in modern car diagnosis.

- Compression Testers: Checks engine cylinder compression levels. A key tool for detecting engine health issues.

Workshop Tools Found in Garages

Garage workspaces rely on larger equipment to store tools and power air-based systems. These workshop tools improve workflow and keep the environment safe and organized.

- Air Compressors: Power pneumatic tools like impact wrenches and spray guns. A central device in most workshops.

- Workbenches: Solid surfaces for assembling, hammering, or inspecting components. Often include vises and lighting.

- Tool Cabinets: Organized storage with drawers and locks. Keeps tools sorted and secure.

FAQs

Common tools include wrenches, screwdrivers, pliers, hammers, and multimeters. These cover most repair tasks.

Not always, but power tools like drills and impact wrenches save time and improve accuracy in tough jobs.

An OBD scanner reads error codes from a vehicle’s computer system. It helps detect problems quickly.

Torque wrenches ensure nuts and bolts are tightened to the correct level. This prevents damage and keeps repairs safe.

Wrench – Used to tighten or loosen nuts and bolts.

Screwdriver – Used to turn screws (flathead or Phillips types).

Pliers – Used to grip, twist, or cut wires and small parts.

Socket Set – Includes sockets and a ratchet handle to work with bolts and nuts.

Hammer – Used for hitting or adjusting metal parts during repairs.

You May Also Like